ISO Certified

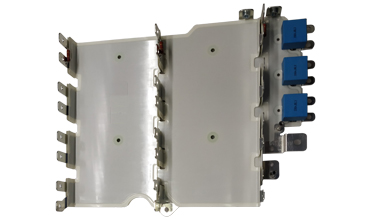

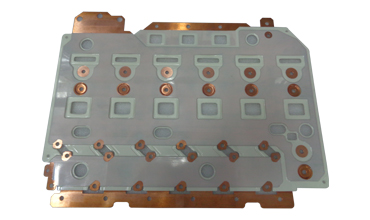

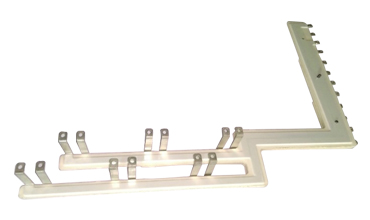

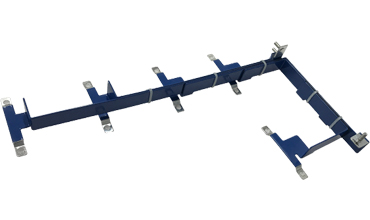

SVM - Bus Bar

| Various Types: | |

|---|---|

| Description: |

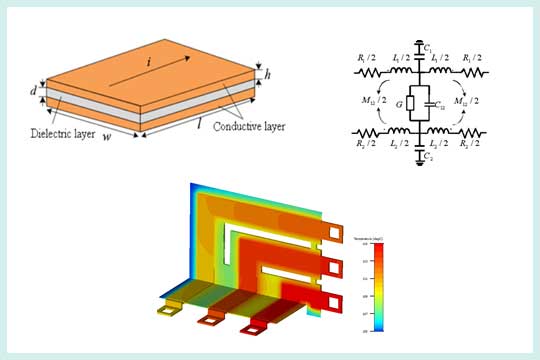

Power Electronics often requires very low inductive interconnections, especially in the medium-high power range. The most common solution to reach stray inductance values around some tens of Nano-henries and even below is to use a bus-bar structure. This "simple" assembly of copper sheets is intended to link several points of the structure, and to stay as Equi-potential as possible. The role of a bus-bar is to link several points of a power electronics converter: capacitors, semiconductors and often to achieve series or parallel association of these devices. |

| Standards: |

IEC 60601-1, ASTM D 1062, ANSI C37.20, BS159 |

| Specialization: |

Multi-Layer bus bar development Low Inductance can be achieved Low level of Partial Discharge can be achieved (less than 10Pico Coulomb) Thermal Modelling of Bus bars

|

| Geometries: |

Any Special Geometry |

| Conductor: |

Cu-ETP Electrolytic tough pitch high conductivity copper CW004A (formerly C101 – (AS per JIS - C1100)) Cu-FRHC Fire-refined tough pitch high conductivity copper CW005A (formerly C102) Cu-OF Oxygen-free high conductivity copper CW008A (formerly C103) |

| Applications: |

Interconnection of Capacitor Links, DC Link, IGBT Power Module, Power and Measuring Components, High Current Inductors etc for various markets like Power Electronics, Wind Energy, Solar Energy, Aerospace Application, Military Application, and Transportation. |