ISO Certified

SVM - Facility

To convert your concepts in to reality in Magnetic Components. SVM can play a significant role in your Product Design where Magnetics is a vital component; in simple words SVM can be your Strategic Solution Provider for your Special Magnetic components.

SVM Design and Technology group works as an extended arm of customers Innovation Team in understanding the Specification, Criticality and the time lines of the Project implementation.

Design Organization

Electrical, Electronics, Mechanical (Bobbin, Clamps and brackets)

Design and simulation Capability for Inductors, Transformers, Hall Effect Current Transformers, Actuators, Solenoids.

Power Converters, Stabilizer for Medical Equipment’s.

Design and Development for Molded , Laminated , Epoxy powder coated , Nickel& Golde plated, Silver Plated , Brazing&Tin Plated , Flexible busbars and other Press Components.

Knowledge, Expertise & Techniques

The Team at SVM can Engineer your ideas and convert them into End use Components

MATLAB, FEMM Modelling and Thermal Simulation of Magnetic components

Reliability of components evaluated using Thermal Cycle, Random Vibration Test and Packaging Drop Test for Shipping and Handling

Load Test for High Current Inductors and Linear Power transformers to check the temperature rise at actual loading pattern

Support for End use and Application

The Team at SVM Interact with Customers and provide solutions for End use and Application

Functional test set up developed for Variable Frequency High power test bench to test the transformers and inductors

Topologies – Full Bridge, Half Bridge, Push-Pull, Forward with loading facility.

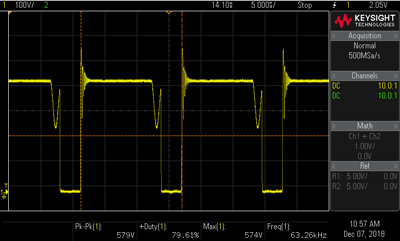

Flyback Transformer Testing Set up

Frequency – Up to 133 kHz

Rating - Up to 250VA

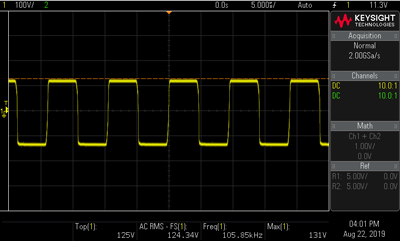

High frequency Transformer Testing set up

Frequency – Up to 100 kHz

Rating - Up to 25kVA

Waveforms:

Full Bridge

Flyback

Lab Facility as per UL Safety Requirements

Partial Discharge Test up to 100kV AC

Impulse Testing Facility upto 100kV DC (Both Lighting and Switching Impulse)

Load Test up to 50kVA (50HZ operating frequency)

Dielectric Strength Test both AC and DC

Precision LCR Magnetic Analyzer for measuring Inductance, Capacitance and Resistance

DC Bias Test up for Inductors

Temperature Data Logger

Magnetics Manufacturing Facility

Multi spindle CNC Winding Machines

Automatic Test equipment’s (ATE)

Copper Foil Winding Machines

Vacuum Impregnation plant

Busbar Manufacturing Facility

Automatic Pressure Gelation Machine ( Resin Cast)

Amada CNC Turret Punching Machine

Amada CNC Bending Machine

AIDA Pneumatic Press for Blanking and forming

CNC PET Film Cutting Machine

Hot Press for Lamination

Powder Coating Plant

Plating Plant

Resistance Brazing and Pressure Welding Setup

PEM Nut and Stud insertion Machine.

Backward Integration

Round Litz Wire up to 350A Current Rating

Rectangular Type 8 Litz wire up to 350A Current Rating

Press Components

Bobbin manufacturing both Thermoset and Thermoplastic

Sophisticated Tool room

Lamination Stamping Facility

Thermoforming Packaging Trays

Special Purpose Machines (SPM)

Builds special jigs, Fixtures, Machines to bring out Customized Products